Discover how our integration with Screens enhances AI contract review, negotiation, and confidence with AI on the inside™.

Explore the differences between manual vs automated contract management and how automation can streamline your business operations.

Understanding AI and how it can help business is all the rage. Understanding why businesses aren't using AI can be a head scratcher. Here's are the biggest reasons why not.

Discover how effective contract management in procurement streamlines operations, reduces risk, and maximizes supplier relationships.

According to data from Healthcare Finance, roughly 60% to 80% of an organization’s transactions are governed by contracts.

Discover how effective contract obligation management can transform your business. Learn five key ways to avoid auto-renewals, never miss discounts, manage compliance risks, build strong business relationships, and drive efficiencies.

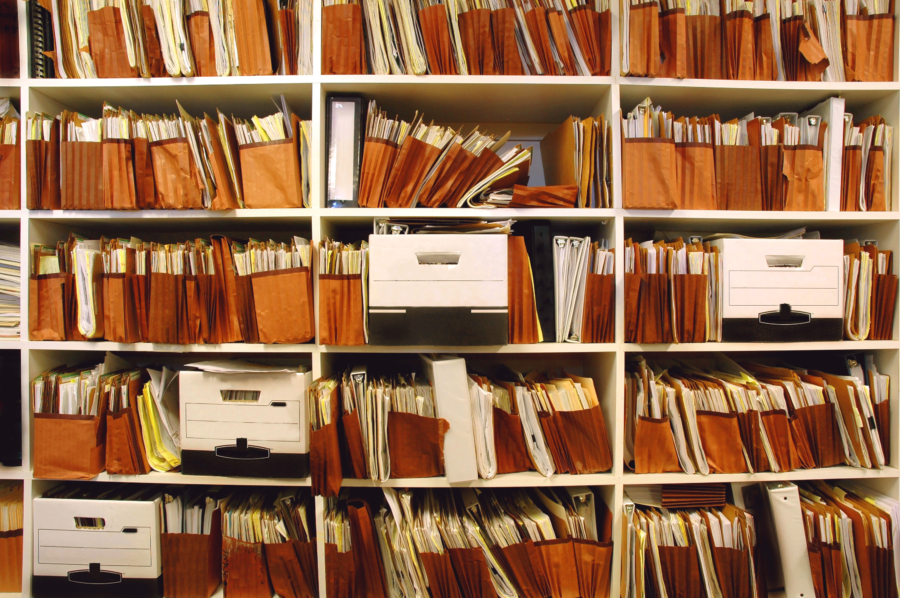

Contracts are a vital (and unavoidable) part of doing business. Contract management often means balancing many moving parts, from drafting to renewing.

New to CLM? This guide walks you through how to evaluate, implement, and optimize a contract lifecycle management platform for your organization.

Discover the key differences between Salesforce’s contract management features and a robust Contract Lifecycle Management (CLM) solution.

Learn how you can build a growth strategy, optimize your contract process, and benefit from increased revenue and savings.